Wiki

Overview

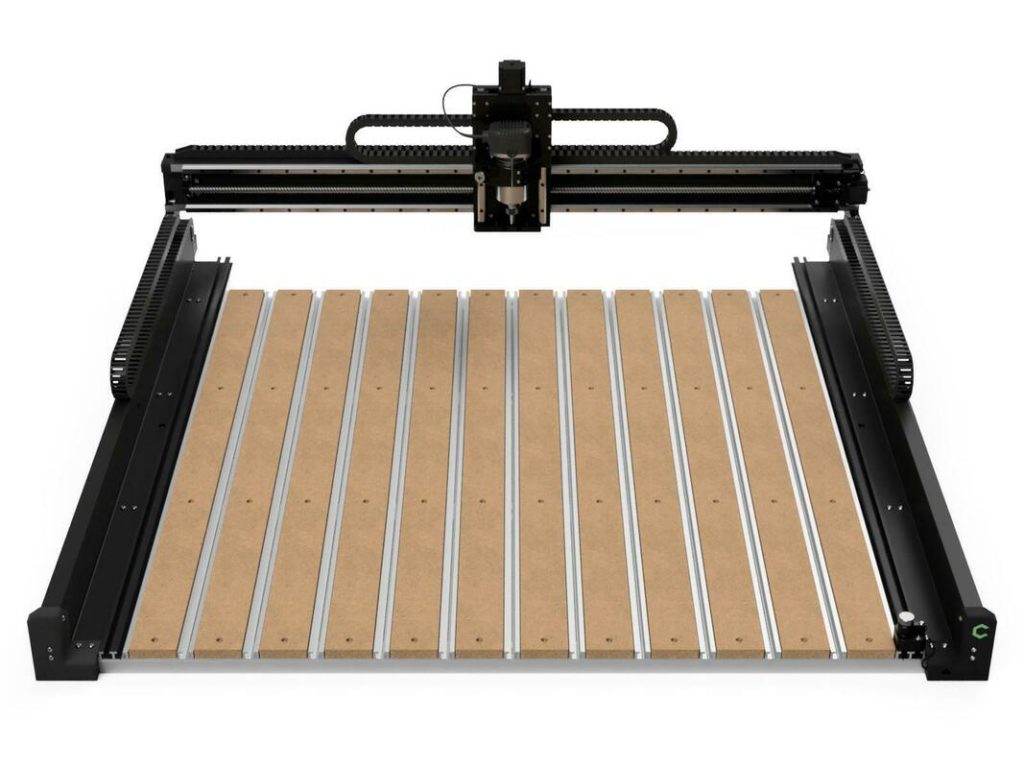

| Name: Shapeoko |

| Location: CNC Area (Refrigerator) |

| Status: Beta/Operational |

| Training: Required |

| Slack Channel: #project-shapeoko5, #help-cnc |

| Owner: Denhac |

Training

Operation

It’s a new machine. We’re still working out kinks and polishing documents, policies, and procedures.

The machine is available for use, but you have a heightened responsibility to be attentive and informed.

Be diligent. Do research. Use your head.

Safety

Clothing & Gear

- eye protection — safety glasses or goggles which are suitably impact resistant

- hearing protection — ear plugs or muffs, for long jobs doubling these up may be desirable. Hearing damage is cumulative and irreversible, so one should err on the side of caution

- respiratory protection — a filter or respiratory mask suited to the dust generated by the material being cut should be worn

- Ensure clothing, hair, and/or jewelry cannot become caught in the machine.

- Never reach into the machine’s working envelope while it is running — long sleeved shirts and pants and suitable footwear is suggested, when doing metal-working, gloves and an apron are recommended.

Guidelines

- Use care when handling endmills, both to avoid being cut, and to avoid damaging them. Handling them with suitable gloves, or using a cloth to avoid contaminating them is recommended. Inspect them carefully before each use and ensure that they are securely held by the collet.

- Never leave the machine running unattended/unsupervised.

- Safely dispose of milling debris — recycle or safely dispose of milling debris and dust, keeping in mind flammability, (potential) spontaneous combustion, and chemical considerations. Even natural materials can have surprising implications for disposing of them, e.g., walnut wood dust is aleopathic (inhibits plant growth) and an irritant to the skin and breathing tract and potentially poisonous to some animals in addition to the typical spontaneous combustion hazard which sawdust poses.

Setup

TODO

Prerequisites, how to turn on the machine, key things to check to ensure it is operating correctly.

Usage

TODO

Detailed steps to operate the machine.

Monitoring

TODO

What to keep an eye on while operating machine.

Shutdown & Cleanup

TODO

Detailed instructions for how to shut down the machine, where to put things away, specific cleanup steps.

Troubleshooting

TODO

| Symptom | Cause | Solution |

|---|---|---|

Accessories

The Shapeoko 5 VFD Spindle supports ER-11 collets and comes stocked with 1/8″ and 1/4″ collets.

Endmills

| # | Flute | Type | Shank | Applications | Materials |

|---|---|---|---|---|---|

| 201 | 1/4″ | Flat Cutter | 1/4″ | Milling, Cutting | Wood, Aluminum, Plastic, Brass, Copper |

| 202 | 1/4″ | Ball Cutter | 1/4″ | Milling, Cutting | Wood, Aluminum, Plastic, Brass, Copper |

| 301 | 1/2″ | 90° V-Bit Cutter | 1/4″ | Engraving, Carving | Wood, Plastic |

| 302 | 1/2″ | 60° V-Bit Cutter | 1/4″ | Engraving, Carving | Wood, Plastic |

| 101 | 1/8″ | Ball Cutter | 1/8″ | Milling, Cutting | Wood, Aluminum, Plastic, Brass, Copper |

| 102 | 1/8″ | Flat Cutter | 1/8″ | Milling, Cutting | Wood, Aluminum, Plastic, Brass, Copper |

| 251 | 1/4″ | Downcut Flat Cutter | 1/4″ | Milling, Cutting | Wood, Plastic |

Materials

TODO

Information on available materials and where they can be found. Also information about any allowed/disallowed external materials.

Files & Resources

- Product Page

- Proposal

- Shapeoko Tutorials

- Assembly Guide

- [Video] Assembly Overview

- [Course] Carbine > Getting Started With CNC

- [Course] Carbine > Running a Shapeoko

- [Course] Carbine > Getting Started with Carbide Create

- [Course] Carbine > Your First Five CNC Projects

- Shapeoko FAQ

Specifications

| Name | TBD |

| Manufacturer | Carbine 3D |

| Year Released | 2022 |

| Model | Shapeoko 5 Pro |

| Serial No. | Serial number |

| Software | Carbine Create, Carbine Motion, V-Carve |

| Spindle | VFD Kit |

| Cutting Area | 4′ x 4′ x 6″ |

| Total Z Travel | 6.1″ |

| Table to Z axis Clearance | 4″ (5″ without Hybrid table) |

| Gantry Shift distance for joinery | 3.15″ |

| T-Slot Spacing | 4.04″ Center-to-center |

| Step Length X/Y | .012mm |

| Step Length Z | .006mm |

| Ballscrew X/Y | 16mm diameter, 20mm pitch with custom wiper |

| Ballscrew Z | 16mm diameter, 10mm pitch |

| Ballscrew Accuracy | +/- 50um per 300mm |

| Linear Rails | HG-15 |

History

- Proposed by Justin

- Approved by board and ordered 2/2023, estimated ship date May 19th